Desiccant air dryer

Working conditions and design parameters

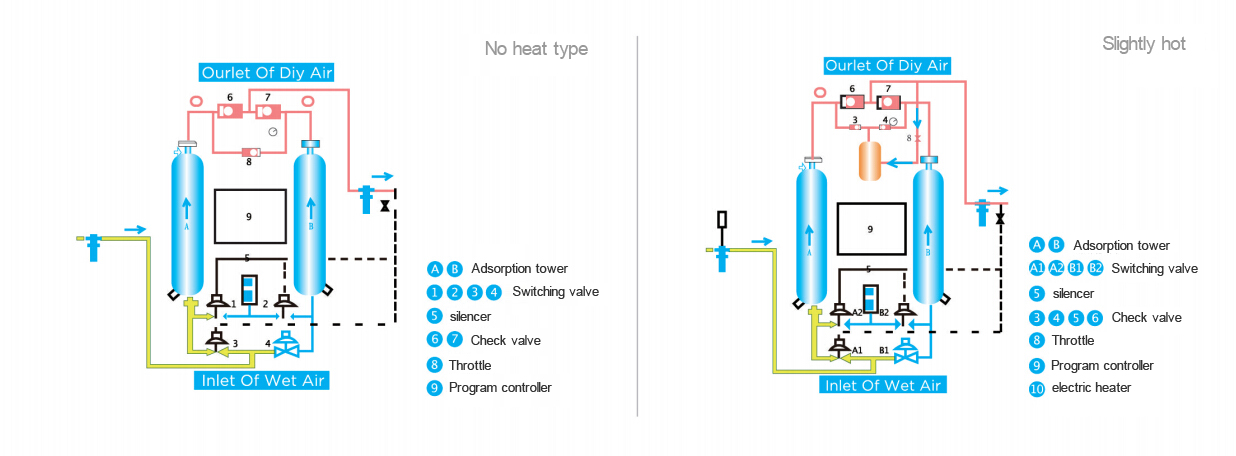

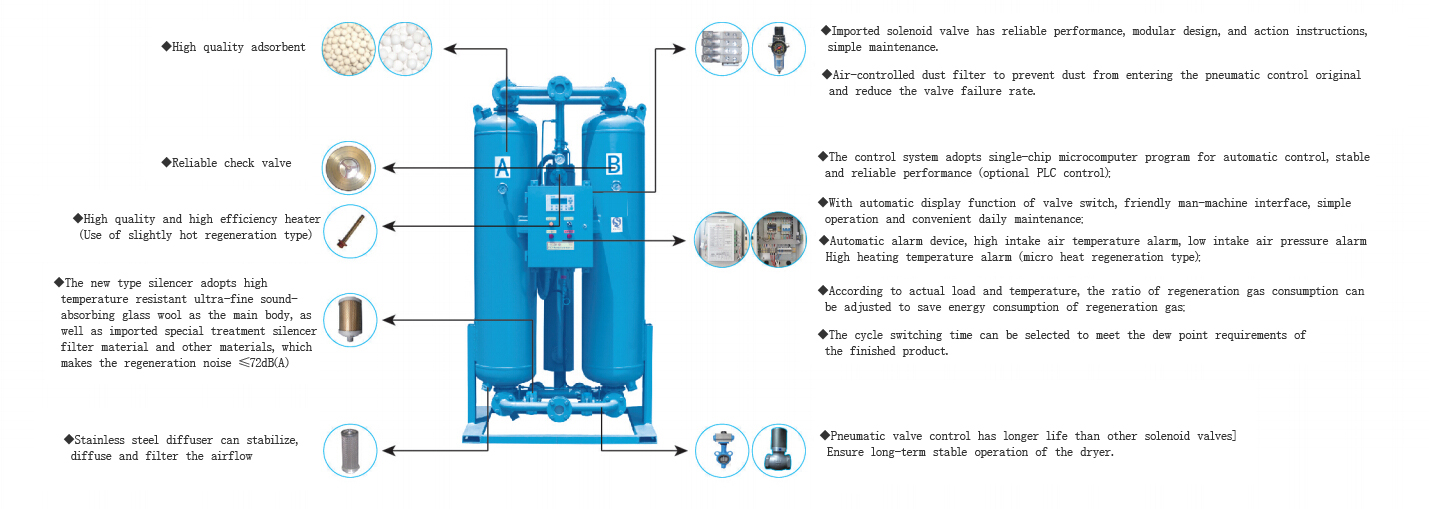

The micro-heated desiccant air dryer combines heat purge and heatless purge, and heats the purge air to reduce its consumption. The shortcomings of short switching time of compressed air dryer, large consumption of purge air and waste of thermoelectricity are effectively avoided. The product has reasonable switching time and low consumption of purified air, making it the most economical adsorption dryer。

-

Regeneration gas volume: ≤4-6%

Intake oil content: ≤0.01ppm

Work cycle: T=60-80 minutes

Voltage: 380V/50Hz

-

Intake air temperature: 0℃-45℃

Working pressure: 6-10Mpa

Pressure dew point: -40℃-70℃

Dryer: activated alumina or molecular sieve