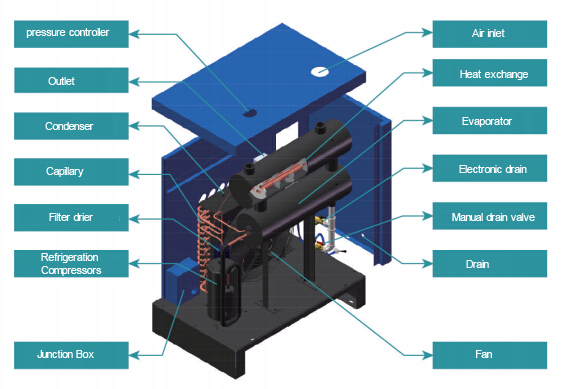

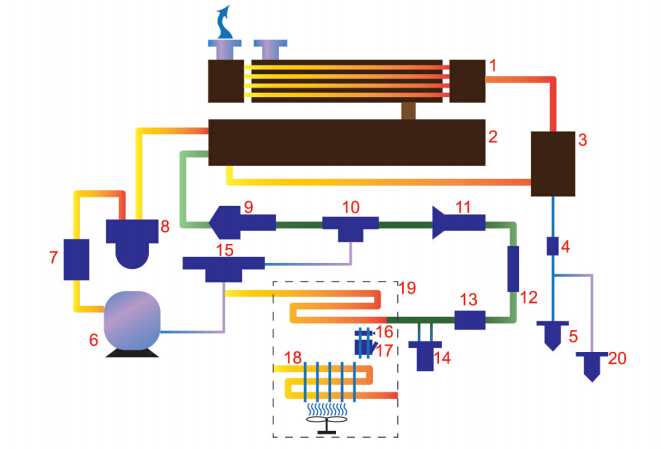

Refrigerated compressed air dryer

The copper tube heat exchanger, evaporator and condenser are all treated with anti-corrosion treatment. The design is simple and reliable, and the discharge pressure dew point is stable at 2-10℃. Advanced control system, equipped with pressure gauge, high and low overpressure and overload protection indication. Pollution.

Cooling method: air cooling/water cooling

Cooling method: air cooling/water cooling  Processing gas volume:1.2-400m³/min

Processing gas volume:1.2-400m³/min  Refrigerants:R134A\R407C

Refrigerants:R134A\R407C -

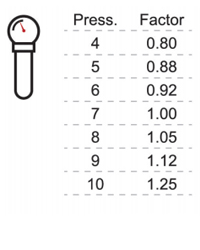

Inlet pressure: 8 bar

Working pressure: 13 bar

Pressure loss:0.2 bar -

Pressure dew point: 2℃~10℃@PDP

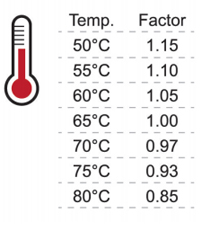

Intake air temperature: 5℃~80℃

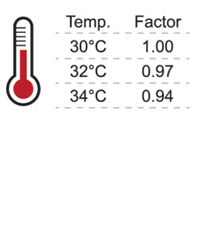

Ambient temperature: 5℃~40℃

Intake air temperature: 80℃